Interested? Contact us to start a sample order, we will offer special discount!

Request A QuoteOutstanding Features Make Us Stand Out

Customization is possible

Customized Logo Marking

Customized Color

Customized Packaging

Customized Segment Shape

Quality Control Can be Seen Throughout Production

Frequently Asked Questions

You no need to worry about that, for every piece of cup wheel, we will mark the bond type and grit size on it. Also, we will put label on the box. With all this information, you can identify the cup wheels easily.

Meanwhile, if you have your own SKU code, that will be perfect, we can mark the code on the cup wheel, or we can print the label with that code.

Customized packaging is available if the quantity meets our MOQ.

There isn’t a standard lifespan of the diamond cup wheel, it all depends on the cup wheel types and the application. So, how to judge a worn cup wheel needs to be replaced or not? A simple way is to look at the gap between the guard and the cup wheel, if the gap is too small, the cup wheel rim is very close to hit the floor, then it is the right time to remove the worn cup wheel and install a new one.

If you can do re-tipping at your side, we will supply the loose segments.

The normal diamond segment cup wheels are not designed for wood. We have specially designed cup wheel for removing the paint on wooden floor, this cup wheel has vacuum brazed segments. Pls contact us if you want to find the cup wheel for wood?

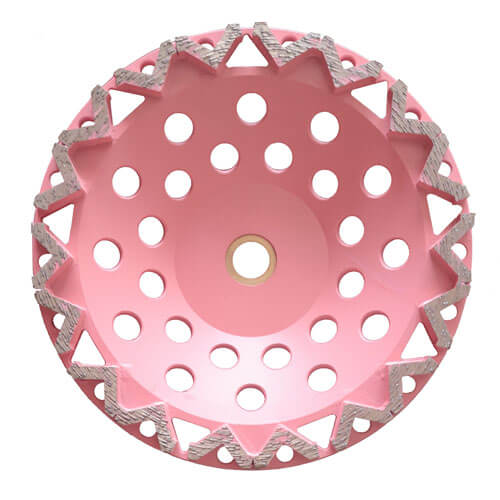

sometimes you will see there are small holes on the diamond cup wheels, these small holes are not flaw, instead they are drilled on purpose. From the appearance, the cup wheel looks smooth and fine, however, the weight of every piece of diamond segment is not 100% uniform, some pieces maybe heavier, because of the weight difference, the cup wheel will become vibrated at high rotation speed. Normally, we will test the dynamic balance of the cup wheel and find the heavier segments, then we will drill small holes around the position of that segment, the small holes will reduce the weight. So, drilling small holes on cup wheel is an effective way to correct the balancing of the cup wheel.

There are two main manufacturing technique on the diamond cup wheels: sintering and silver soldering.

The sintering cup wheels use the cold pressing method, press the diamond segments to their forms directly on the grinding wheel's body, and let the segments connect with the wheel's body via teeth, slots or other manners. Then, put the grinding wheels into sintering furnaces to sinter without press. As it is no press sintering, so the sintering cup wheels don't have long lifespan, it is only for general use.

The Silver soldering cup wheels use the hot-pressing method, the hot-pressing method is to directly sinter the diamond segments in molds under a certain pressure in the dedicated sintering press machine, and then fix or connect the diamond segments onto the grinding wheel’s body via high-frequency welding, laser welding or mechanical mosaic method.

Diacutex diamond cup wheels start with the coarsest disc (10 grit) and works through to the finest, 400 grit. Generally, the concrete floor preparation process will start with a 30-grit disc and progress incrementally through to 80-grit. A finishing pass using a 150-grit disc will prepare the surface for sealer application. Most customers are satisfied with the result at this point.

For fine grinding (sometimes called "polishing"), the bond should be harder and the diamonds' quality can be lower, as in this case the diamonds can last longer and a hard bond can also help the precision of the process.

Concrete surfaces can vary widely and will determine if hard or soft bond diamond cup wheels are required. Generally, this selection will be made by trialing the cup wheels. Hard concrete results in a soft nonabrasive dust so a soft bond disc is required to help expose the diamond particles. If you find the machine is grinding too slow try a softer bond grinding disc. The opposite applies for grinding softer concrete. Use a hard bond disc to prevent unnecessary disc wear. If you find the disc is wearing too fast switch to a hard bond disc. You can also visually inspect the disc and if too little diamond is exposed or the surface is getting hot then switch to a soft bond disc or a disc with fewer segments.